Headstock

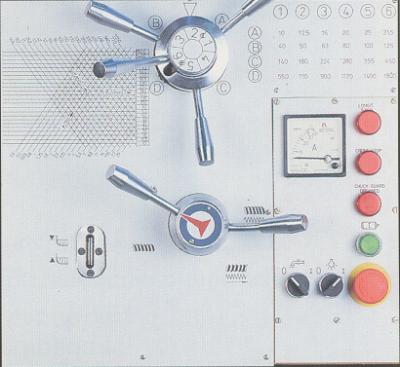

- A fully clutched and pressure lubricated headstock provides an extraordinary

24 spindle speed selection in a 1.24 ratio power multiplier. Full 24

spindle speed choice yields an optimum performance speed matchup for

material depth of cut; feedrate and surface finish needs.

Seperate forward and reverse main spindle clutches give fast but smooth

engagement of power to the main spindle. Main drive motor fatigue and

premature failure is reduced by eliminating frequent "start/stop/reverse"

as found in lesser quality lathes. This reduces electrical consumption

also and improves economy of operation.

- Wide faced analog type load meter shows the operator an instant picture

of cutting load conditions for maximizing performance and efficiency.

- Warning indicator lamps instantly depict fault conditions of Carriage

Longitudinal Over Travel, Cross Slide Overtravel, Chuck Guard Out of

Position. Any one lamp ignition will stop the spindle immediately until

the fault condition is cleared. Big Mushroom E-Stop button shuts everything

down fast.

- Selector levers for right and left hand threading including standard

and wide pitch options are conveniently located right at the headstock.

- Large easy to read lubrication sight gauge provides the operator with

headstock oil flow conditions.

|